Water Treatment Plants

We are thoroughbred Water Treatment Professionals and clearly stand apart from the crowd. The difference begins from the design itself. With basic raw water quality, product water quality and capacity requirements, all required operational and maintenance provisions, all quality and performance monitoring provisions etc. taken care of in minute detail; more often than not, our products are extremely well designed; well engineered, high performing and long life.Whether it is a simple filtration plant or a complete ultrapure water plant and anything in between, this is the subject knowledge and experience, commitment to quality and standards, and professionalism that matters in delivering a complete and a proper solution to the customer's requirement. We have been into water treatment for last 35 years, have in depth knowledge of water chemistry, expertise in designing and execution, a fully equipped factory and trained people to ensure the best for our customers.

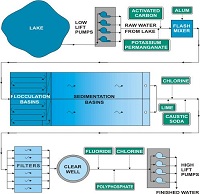

We have over 30 years of experience in providing reliable and sustainable solution for all type of water treatment products e.g. Membrane Separation:Reverse Osmosis; Water Disinfection Equipment; Hydro Pneumatic System; Hot Water Solutions; Water Supply System; Filtration:Sand Filters,Media Filters,Micron Filters,Cartridge Filters; Gravity Separation; Coagulation; Flocculation; Adsorption Filters; Ion Exchange Processes:Water Softening; Demineralisation; Dealkalisation; Phase Distribution ;Sterilisation/Disinfection:Chlorination,UV,Ozonation,Distillation ;Chemical Dosing.

Filteration

Activated Carbon Filters

Micron Filters

Water Disinfection Equipment

We have a wide range of water disinfection equipment to choose from. Chlorinators (Liquid and Gas), ultraviolet sterilizers and ozonizers are the most common methods of disinfection, followed by Nano Filtration, Ultrafiltration and Reverse Osmosis.

Clarifiers

Flash Mixtures & Flocculaturs

Chemical Dosing Systems

ph / ORP Controllers

Water Softening Plants

AmritNeer Water Solutions water softening plants are simply top of the line. Best performance, least operating cost, no operational hassles and long life are assured.In the plant itself; all provisions for maintenance are made. In addition to the normal access manholes, separate resin outlet is provided. The strainer plate is made accessible both from the top as well as from the bottom to make sure that every internal nook and corner of the plant can be accessed for maintenance purposes. We use only Diaphragm Valves in our water softening plants as these are best suited for smooth control of flow rates ( flow rates are very important in backwash – regeneration – rinse and service operations ) as against ball valves or butterfly valves.

Brine Tank: Narrow mouth plastic water containers provided as brine tanks leave a lot to be desired. No provisions are made for salt charging, cleaning, drain and overflow rendering the brine tank as good as not being there.

Brine Agitation: Water softeners require a large quantity of salt to be dissolved in water for brine preparation and regeneration. This is impossible manually. Thus brine preparation is always incomplete, the plant does not get proper regeneration and does not perform well. Brine agitation systems are a standard on all our water softening plants (100 ltrs resin capacity onwards ) .

Brine Ejectors: Water softener will work best only if it gets right quantity of brine in right concentration at the right flow rate and all this has to be ensured by brine ejector. We use only the standard brine ejectors with accurate suction ratio and tested capacity matching to the plant requirement.

Brine Distribution: We provide separate brine distributor ( other than inlet distributor ) in all plants to ensure uniform distribution of brine over the resin bed and maximum regeneration efficiency. Simply connecting the brine discharge of ejector to the inlet line reduces the regeneration efficiency.

Brine Density: To make sure that only the brine of right strength is used for regeneration ( not depending upon the weight of raw salt – which more often than not is heavily contaminated with silt plus not assuming the dissolution process to be complete ) ; we include brine density meter as standard supply with every plant.

Under drain System: We design under drain systems ( Strainer Plates ) with sufficient passage to make sure that the brine never backflows into the brine tank due to the flow restriction caused by the underdrain system.

The construction: All required engineering standards and best practices are followed in manufacture of plants.

The Corrosion Protection: The plant vessel and the piping are provided with epoxy coating ( after sand blasting ) on all internal surfaces . The brine tanks have rubber lining to ensure total corrosion protection.

Water Demineralisers / Dealkalisers

RO Plants

Meticulously designed on individual raw water quality and requirement basis. We always maintain the operation parameters within the prescribed limits so that the plant never underperforms. Manufactured in modern fully equipped factory with highly trained workers, use of proven quality components, specially developed mostly weld free piping components, high quality instrumentation, our plants naturally stand apart from the crowd. Besides; most competitive prices and reliable after sales services are assured.

What makes us special is our 35 years experience in water treatment; our deep understanding of water chemistry, our commitment to quality and originality, our professionalism and our 100% dedication to the customer satisfaction. Competition doesnt even come close when it comes to quality. Buy one now enjoy the benefits.

Ultra Filters

Iron Removal Systems

Water Supply Systems

Hydro Pneumatic System

Consistent, uninterrupted flow and pressure are ensured with our systems, not withstanding whether it is a small system made for one house or a huge system made for an entire establishment.

Features:

Hot Water Solutions

Geysers; because of their limited storage and heating capacity are extremely inconvenient. They require a long start up time; start giving cold water within a few minutes and even when they are supplying hot water; mixing at the mixer tap is never smooth and one cannot expect a consistent temperature even for a few minutes. Besides; they are not designed to take pressure and hence start leaking in pressurized water supply.

Central hot water systems are the solution, particularly where the hot water is to be supplied to a number of points simultaneously and also hot water requirement varies with time.

Central Hot Water Systems are designed with sufficient storage capacity; the stored water is heated over the non usage period, and hot water is available as and when required. Hot water systems are able to utilize naturally available heat viz. the heat present is sunlight via the solar heaters, the heat present in the environment via heat pumps, thus offering great economy in operation.

Central Hot Water Systems make use of a combination of heating methods viz. Solar, Heat Pumps, Direct Electrical Heating, Gas Boilers etc. to ensure maximum economy and efficiency.

The success of a central hot water system depends heavily upon designing. Assessing the heating capacity requirements under worst conditions, assessing storage capacity requirements according to peak load time requirements, selecting theright heating method, right equipment designing and making effective on line sensing and control etc. are the vital factors. This is where ’ STAR’ expertise comes to help. Most meticulously designed and executed central hot water systems are the hallmark of "AmritNeer Water Solutions." .

We make and offer Filtration Plants in FRP and MSEP constructions, manufactured according to best engineering standards and practices.

Features: